In recent years, the fertilizer industry has undergone significant advancements due to the integration of industrial automation and digital technologies. At Xincheng, we are committed to transforming fertilizer production lines by introducing innovative technologies like the Bulk Blending Fertilizer Equipment and BB Fertilizer Blending Line. These tools are reshaping the way fertilizers are blended, making the entire process more efficient, environmentally friendly, and sustainable.

Smart Weighing Systems and Real-Time Monitoring

At Xincheng, we understand the importance of precision when it comes to blending fertilizers. Our Bulk Blending Fertilizer Equipment integrates smart weighing systems that provide accurate measurements in real time. This technology ensures that each ingredient is mixed in the correct ratio, eliminating human error and enhancing the overall consistency of the fertilizer. The real-time monitoring capabilities also allow operators to track the production process continuously, ensuring that any issues can be addressed instantly, reducing downtime and boosting productivity.

Data-Driven Formulation Management

With the advent of digital tools, fertilizer blending has evolved into a more data-driven process. The BB Fertilizer Blending Line at Xincheng is equipped with advanced software that allows for precise formulation management. This system ensures that the right nutrient balance is achieved for specific crop needs. It not only optimizes the use of raw materials but also helps in creating custom blends that cater to diverse agricultural requirements. The ability to analyze data and adjust formulas accordingly helps improve the quality of the fertilizer and boosts crop yields.

Automated Packaging and Conveyor Systems to Enhance Efficiency

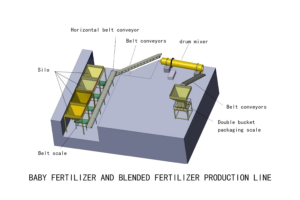

To complement our Bulk Blending Fertilizer Equipment, we have integrated automated packaging and conveyor systems into our production lines. This automation reduces the need for manual labor, speeds up the process, and minimizes the chances of contamination. The conveyor systems ensure that blended fertilizers are packaged efficiently and transported without delays, allowing us to meet demand quickly and keep up with the growing agricultural industry’s needs.

Impact of Digital Management on Quality and Operations

At Xincheng, digital management systems are at the core of our production process. These systems offer enhanced quality control, providing detailed insights into each batch of fertilizer produced. With the BB Fertilizer Blending Line, the entire production process is tracked and documented digitally, ensuring transparency and traceability. This enables us to ensure that only high-quality fertilizers are produced and that our operations are always running at peak efficiency. Additionally, the digitalization of the process allows us to make data-backed decisions that further enhance our operational capabilities.

Conclusion: The Future of Fertilizer Production is Smart and Digital

In conclusion, the future of fertilizer production lies in the integration of smart, automated systems and digital management. At Xincheng, we are excited to be part of this transformation, enhancing the Bulk Blending Fertilizer Equipment and BB Fertilizer Blending Line with innovative technologies that improve efficiency, sustainability, and crop quality. By embracing digital and automated solutions, we are helping farmers grow better crops while reducing the environmental impact of traditional farming practices.