In recent years, cities have been exploring more sustainable ways to manage waste, especially organic waste. With an increasing focus on green development and circular economy practices, transforming urban waste into valuable organic products has become essential. At Xincheng, we specialize in developing efficient solutions that cater to this need. Our organic fertilizer production line and powdery organic fertilizer production line play a crucial role in converting urban waste, such as kitchen scraps and garden waste, into eco-friendly organic fertilizers that benefit both the environment and agriculture.

Kitchen Waste and Garden Waste: Ideal Organic Raw Materials

Urban areas generate vast amounts of kitchen waste and garden debris, both of which are rich in organic matter and ideal for conversion into fertilizers. By using these materials, cities can reduce landfill waste while turning these otherwise discarded items into nutrient-rich products. At Xincheng, our powdery organic fertilizer production line provides a seamless way to handle these materials. The line is designed to efficiently process kitchen waste and garden refuse, ensuring that they undergo proper decomposition and transformation into high-quality organic fertilizers.

Pre-treatment Systems and Fermentation Solutions for Organic Waste

The initial steps in the organic fertilizer production line involve pre-treatment processes that are vital for ensuring high-quality output. The raw materials—kitchen scraps, garden waste, and other organic substances—must first be mixed and prepared for fermentation. Xincheng’s advanced pre-treatment systems, including composting and fermentation technology, facilitate this crucial stage. We use aerobic fermentation in large tanks, where microorganisms break down the organic material in a controlled environment. This fermentation process takes approximately 8 days, ensuring that the material is thoroughly decomposed and transformed into compost, ready for the next stages of production.

The Stability of Powdered Products and Safe Treatment Value

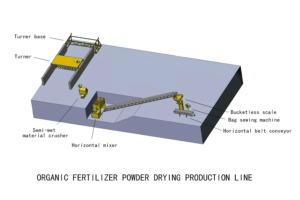

Once the materials are fermented, they undergo a screening and drying process, which is essential for maintaining product quality. At Xincheng, we pay close attention to these post-processing stages to guarantee the stability and purity of the final product. Our powdery organic fertilizer production line is specifically designed to remove excess moisture and ensure that only the highest quality organic fertilizer is produced. This process also contributes to the safety and environmental sustainability of the product by ensuring it is free from harmful pathogens or contaminants.

Xincheng’s Contribution to Urban Resource Recovery Projects

Xincheng’s expertise in organic waste transformation extends to urban resource recovery projects. By integrating our organic fertilizer production line solutions, cities can recycle organic waste more effectively and reduce their environmental footprint. Our equipment helps municipalities and businesses turn waste into a valuable resource, contributing to greener urban landscapes and promoting sustainable agricultural practices. With a focus on automation and efficiency, Xincheng makes it easier for cities to manage organic waste while improving soil quality and supporting crop growth.

Conclusion: Empowering the Green Economy Through Waste Transformation

As urban populations continue to grow, the demand for efficient waste management and sustainable agricultural solutions will only increase. At Xincheng, we are committed to providing comprehensive solutions for transforming kitchen waste and garden refuse into high-quality organic fertilizers. Our powdery organic fertilizer production line is an essential part of the green revolution, helping cities move toward a more sustainable and circular economy. Through our innovative systems, we are not only helping reduce waste but also fostering healthier environments for future generations.