At Xincheng, we understand that the success of modern agriculture depends heavily on the efficiency of fertilizer production. The machinery used in fertilizer production lines is not just an investment in equipment but a commitment to the future of sustainable farming. With over a decade of experience in the industry, Xincheng is focused on delivering fertilizer machines that meet the demands of today’s rapidly evolving agricultural landscape.

The Essential Components and Processes of Fertilizer Production Lines

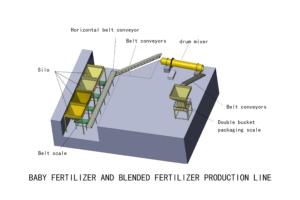

Fertilizer production lines are complex systems that consist of various equipment designed to manage each stage of the production process. Starting with raw material fermentation, we progress through steps such as crushing, mixing, granulation, drying, cooling, screening, and packaging. Each of these steps requires specialized equipment to ensure efficiency and product quality. At Xincheng, we manufacture machines for each of these processes, ensuring that each stage flows seamlessly into the next. Our fertilizer equipment is designed to handle various raw materials and produce high-quality fertilizers with minimal waste.

Tailoring Equipment to Meet the Needs of Different-Sized Factories

The fertilizer production needs of a small local farm differ significantly from those of a large-scale factory. Recognizing these differences, Xincheng customizes its fertilizer machines to suit both small and large operations. Whether it’s a small-scale organic fertilizer line or a high-capacity blended fertilizer production line, our equipment is designed to cater to a wide range of production capacities. This flexibility ensures that every customer, regardless of their scale, can find the right equipment to meet their needs.

Stability and Consistency in Fertilizer Production

The relationship between equipment stability and fertilizer quality is crucial in the manufacturing process of fertilizer. Inconsistent performance of manufacture fertilizer machines can lead to subpar fertilizer quality, negatively impacting crop yields. At Xincheng, we prioritize the durability and reliability of our fertilizer manufacturing machines, ensuring that they operate smoothly over extended periods. Our machines are equipped with the latest technology to maintain consistent performance, which directly influences the quality of the fertilizer produced. High-quality fertilizer is essential for promoting soil health and boosting crop productivity, and we are committed to delivering advanced fertilizer manufacturing machines that support these critical outcomes.

Supporting Sustainable and Eco-Friendly Fertilizer Production

As the world moves toward more eco-conscious practices, the demand for environmentally friendly fertilizers is on the rise. Xincheng recognizes the importance of creating fertilizers that support sustainable farming. Our fertilizer production lines are designed to produce fertilizers that are both effective and environmentally responsible. From organic fertilizers to innovative blended options, we focus on providing equipment that helps produce high-quality fertilizers with a minimal environmental footprint. Our machines play a key role in ensuring that farmers can meet both their production goals and sustainability objectives.

Conclusion: The Long-Term Impact of Fertilizer Equipment on Agriculture

The role of fertilizer production line equipment extends beyond just supporting high-efficiency farming. These machines help farmers produce fertilizers that enhance soil fertility, improve crop yields, and promote sustainable agricultural practices. As a trusted fertilizer equipment manufacturer in China, Xincheng is proud to contribute to the future of agriculture by providing machinery that not only supports high production standards but also ensures a cleaner, greener environment. Through continuous innovation and a commitment to quality, Xincheng will continue to play a significant role in shaping the future of agricultural practices.