In today’s agricultural landscape, ensuring the right balance of nutrients is critical for crop health and productivity. This is where fertilizer blending comes in. A fertilizer blending production line is designed to create customized, mixed fertilizers that suit the specific needs of various soil types and crops. With increasing demand for more efficient and sustainable farming practices, Xincheng has developed advanced bulk blending fertilizer production lines that address these challenges with precision and reliability.

Core Structure and Key Functions of a Fertilizer Blending Line

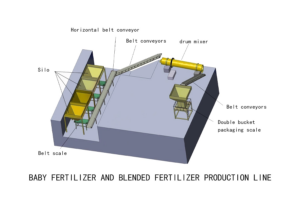

At the heart of any fertilizer blending production line is a series of sophisticated machines that work in harmony to ensure efficiency and quality. The primary piece of equipment, the BB fertilizer blending machine, uses a unique mechanism that alternates between forward and reverse motions. This dual-direction operation allows for better mixing and output of materials, resulting in uniform granules that have optimal moisture content and strength. The system’s design ensures that the fertilizer blending line minimizes clumping during storage, ensuring ease of handling and application for farmers. At Xincheng, we focus on optimizing these processes to create a smooth, high-performance system that reduces downtime and increases productivity.

Accurate Batching and Weighing Systems for Precision Fertilizer Production

One of the critical aspects of a successful fertilizer blending production line is the batching system. At Xincheng, we use advanced batching controls to guarantee accurate material measurements. Our systems can handle throughput ranges of 10-15 tons per hour, offering flexibility to meet various production needs. The batching system is complemented by a precise weighing mechanism that ensures the right amount of each raw material is added to the mix, eliminating the risk of overuse or waste. The design incorporates a unique feeding mechanism that maintains smooth material flow, eliminating blockages that can arise with traditional bucket elevator systems. This not only improves efficiency but also minimizes material compaction, contributing to a more streamlined production process.

The Impact of Blending Technology on Fertilizer Uniformity

The success of a bulk blending fertilizer production line heavily relies on the consistency of the final product. At Xincheng, we understand that fertilizer quality is determined by how well the components blend together. Our fertilizer blending equipment uses an internal spiral mechanism combined with a unique three-dimensional structure that ensures even distribution of each nutrient. This advanced blending technology helps achieve a high degree of uniformity in the final product, which is crucial for balanced nutrient delivery to plants. The result is a fertilizer that not only performs consistently but also minimizes waste, making it more cost-effective for farmers.

Automated Packaging and Intelligent Control Systems

As part of the push for greater automation in the agricultural industry, Xincheng has integrated smart control and automated packaging solutions into our fertilizer blending production line. These systems allow for seamless tracking, batch management, and real-time adjustments to ensure the production process runs smoothly from start to finish. The automated packaging system is designed to handle bulk quantities efficiently, providing high-speed packing and reducing the risk of human error. Through intelligent monitoring and remote control capabilities, the system provides operators with better insights into the production process, helping to maintain optimal performance.

Conclusion: The Value of Fertilizer Blending Production Lines in Precision Agriculture

The implementation of a fertilizer blending production line in modern agriculture can significantly improve both crop yield and resource efficiency. At Xincheng, we believe that the ability to tailor fertilizers to the specific needs of different crops and soil conditions is key to achieving sustainable agricultural practices. Our advanced bulk blending fertilizer production line is built with the latest technologies to provide accurate batching, uniform mixing, and seamless automation. By investing in such a system, farmers can enhance their fertilizer application efficiency, reduce waste, and ultimately support better agricultural outcomes.