In the modern agricultural sector, efficient fertilizer production plays a vital role in improving crop yields and maintaining soil health. One of the innovations that has been gaining traction is the BB Fertilizer Making Equipment—a system designed for batch processing of fertilizers. At Xincheng, we specialize in producing advanced BB Fertilizer Making machines, which are engineered to enhance productivity and efficiency across various agricultural practices. Let’s dive into the technical features and key applications of these innovative systems.

The Technological Advantages of BB Fertilizer Making Machines

The BB Fertilizer Making machine by Xincheng utilizes an advanced mixing mechanism that operates with both forward and reverse motions. This unique design enables the machine to achieve thorough mixing of fertilizer materials, ensuring uniformity in the final product. The internal spiral mechanism combined with the three-dimensional structure ensures that the materials are efficiently blended, allowing for high-quality output with uniform particle size and low moisture content. The result is a fertilizer that retains its strength and does not agglomerate, even during storage.

Precision and Flexibility in Fertilizer Formulation

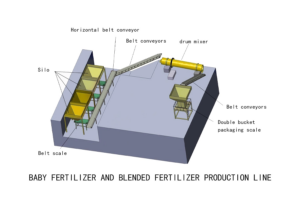

One of the standout features of Xincheng’s BB Fertilizer Making Equipment is its precision in batching. The batching system, a core component of the line, delivers highly accurate measurements for the fertilizer formulation process. The equipment can handle batching capacities ranging from 10 to 15 tons per hour, which is ideal for large-scale operations. The BB Fertilizer Making machine ensures that each batch is mixed to meet specific requirements, allowing farmers to tailor their fertilizers according to the nutritional needs of different crops. This flexibility is crucial for enhancing productivity and optimizing crop yields.

Stability and Output Performance

The stability of the system is another crucial aspect of the BB Fertilizer Making Equipment. Xincheng’s design features a unique feeding mechanism that prevents blockages and material compaction, ensuring smooth operation throughout the production process. The large-angle feeding belt conveyor helps avoid issues like overflow or material jamming, which can slow down production. Additionally, the system’s ability to maintain consistent output with minimal downtime translates to higher efficiency and greater capacity. This makes it an ideal solution for both small and large-scale fertilizer production operations.

Diverse Applications in Agriculture and Horticulture

The versatility of the BB Fertilizer Making machine is evident in its wide range of applications. Beyond traditional agricultural settings, the system is also suitable for horticultural applications, where tailored fertilizers are crucial for specific plant types. The BB Fertilizer Making Equipment supports various types of fertilizers, including blended, formulated, and specialized products, which are essential for maintaining soil health and promoting sustainable agriculture. By enabling customized fertilizer production, Xincheng helps farmers and horticulturists achieve more effective and eco-friendly farming practices.

Conclusion: The Role of Efficient Mixing Systems in Fertilizer Production

In conclusion, the BB Fertilizer Making Equipment from Xincheng is an essential component in modern fertilizer production lines. With its advanced mixing technology, precise batching system, and stable operation, it addresses the key challenges faced by fertilizer manufacturers today. Whether in agriculture or horticulture, this equipment provides an efficient solution for producing high-quality fertilizers, improving productivity, and supporting sustainable farming practices. By embracing these technologies, producers can significantly enhance the quality of their products and meet the growing demand for effective fertilizers.