The increasing scale of modern livestock farming has brought significant environmental challenges, especially in managing animal waste. Improper handling of manure can lead to pollution of soil, water, and air, affecting both local ecosystems and human health. However, this same waste holds immense potential as a valuable resource. Organic fertilizers, made from livestock waste, offer an eco-friendly solution, turning waste into a product that benefits both the environment and agricultural production. This is where the organic fertilizer production line comes into play, transforming livestock waste into high-quality, sustainable fertilizers.

The Role of Equipment in Livestock Waste Resource Utilization

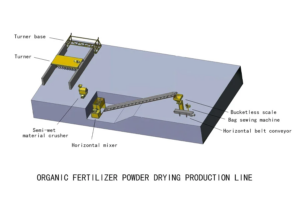

At Xincheng, our organic fertilizer production line is designed to efficiently process livestock manure and other organic materials into valuable fertilizer products. The equipment is built to handle the challenges of large-scale farms, ensuring that waste is effectively converted and its resource value maximized. With a specialized focus on the powdery organic fertilizer production line, Xincheng provides a streamlined process that guarantees high efficiency and product quality. The process starts with the collection of manure, followed by mixing it with beneficial microorganisms to initiate composting, setting the stage for further processing.

Raw Material Fermentation, Deodorization, and Crushing Processes

One of the critical stages in the powdery organic fertilizer production line is the fermentation of raw materials. In our system, composting is carried out in a controlled environment using specialized fermenters, which maintain optimal oxygen levels and temperature for microbial activity. This ensures complete breakdown of organic matter, eliminating odors and pathogens. After fermentation, the raw materials undergo crushing to reduce particle size, making it easier to handle and process into finished products. The crushed materials are then subjected to screening to ensure consistency and purity before further processing.

The Production Process of Powdery Organic Fertilizer and Stability Control

Xincheng’s organic fertilizer production line includes advanced drying and screening systems, which play a crucial role in ensuring the stability and quality of the finished product. The materials are dried to reduce moisture content, preventing clumping and enhancing shelf life. The dryer is designed to efficiently handle the volume of materials typical in large-scale farming operations. Once dried, the materials are carefully screened to remove any impurities, ensuring that the powdery organic fertilizer meets high standards for quality and effectiveness. The final product is then ready for packaging.

Real-World Applications: Organic Fertilizer Production Lines for Large Farms

Xincheng’s organic fertilizer production line has already proven its value in numerous large-scale farms. Our equipment is tailored to meet the specific needs of these farms, where managing waste efficiently and sustainably is crucial. By implementing a powdery organic fertilizer production line, farmers can not only reduce waste management costs but also create a profitable product that enhances soil health and supports sustainable farming practices. These production lines provide a seamless solution, ensuring that livestock waste is efficiently converted into a resource that contributes to the overall health of the farm and the environment.

Conclusion: Advancing Sustainable Agriculture with Efficient Equipment

In conclusion, at Xincheng, we are committed to providing innovative solutions for livestock waste management. Our organic fertilizer production line offers a practical approach to the resource utilization of organic waste, benefiting both the environment and agricultural productivity. By integrating advanced equipment and processes, such as the powdery organic fertilizer production line, we help farms achieve greater sustainability and reduce their environmental impact. As the demand for sustainable farming practices grows, our technology continues to play a pivotal role in advancing green development within the livestock industry.