With the rapid development of precision agriculture, the demand for customized fertilizers has significantly increased. This shift demands advanced equipment and optimized processes to meet the varying needs of crop nutrition. At Xincheng, we specialize in providing a blending fertilizer production line designed to optimize the blending process, ensuring efficient, effective, and environmentally friendly fertilizer production. Our production line for bulk blending fertilizer is designed to meet these growing demands, combining innovation and precision.

Meeting Customization Needs with Advanced Blending Systems

As agricultural practices evolve, the ability to produce fertilizers tailored to specific crop needs has become crucial. The blending fertilizer production line offered by Xincheng is engineered to provide flexibility and precision in mixing different nutrient components. Our technology enables the creation of a wide range of formulations, allowing for the exact proportion of essential nutrients to be blended, ensuring optimal crop growth. The production line for bulk blending fertilizer integrates advanced systems that support the customization of blends, enabling farmers to tailor their fertilizers to specific soil conditions and crop types.

Improving Raw Material Management and Weighing Accuracy

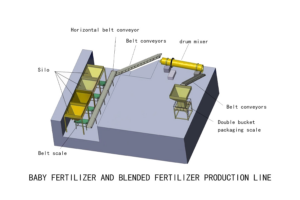

Accurate material batching is key to producing high-quality fertilizer. At Xincheng, we understand the importance of precise raw material management. Our blending fertilizer production line incorporates a highly accurate batching system with a specialized feeding mechanism that ensures a smooth and consistent flow of raw materials. The production line for bulk blending fertilizer allows for accurate dosing within a range of 10-15 tons per hour, minimizing waste and ensuring that each batch meets the required nutrient specifications. This optimization helps maintain the consistency and quality of the end product.

Ensuring Quality Control During the Blending Process

Quality control is a critical factor in the fertilizer manufacturing process. At Xincheng, we’ve designed our blending fertilizer production line to incorporate a thorough quality control mechanism that monitors the blending process in real-time. From material handling to the final product, our technology ensures uniform particle size, low moisture content, and high particle strength. The unique spiral mechanism within the production line for bulk blending fertilizer ensures that no agglomeration occurs during storage, preserving the quality and effectiveness of the fertilizer.

Maintaining Consistency and Fertilizer Effectiveness

Achieving consistency in fertilizer production is essential for ensuring that the product performs effectively in agricultural applications. At Xincheng, we focus on stabilizing the final product’s nutrient composition, guaranteeing that it maintains its intended effect throughout its lifecycle. The blending fertilizer production line ensures that each batch of fertilizer is uniform in particle size and nutrient content, which is critical for effective crop nutrition. By optimizing the production process, we help ensure that fertilizers maintain their consistency and effectiveness, thus supporting sustainable and efficient farming practices.

Conclusion: Process Optimization for Efficient Fertilizer Use

In conclusion, optimizing the fertilizer blending process is essential for meeting the demands of modern agriculture. By investing in advanced technologies and systems, such as the production line for bulk blending fertilizer offered by Xincheng, farmers can benefit from improved precision and efficiency. At Xincheng, we are committed to developing innovative solutions that enhance fertilizer production, helping to support the long-term success and sustainability of precision agriculture.