As small and medium-sized fertilizer companies grow, the need for digital upgrading in their production lines becomes more apparent. The demand for a more streamlined, efficient, and cost-effective operation pushes businesses to adopt new technologies. At Xincheng, we recognize the importance of digitalizing the organic fertilizer production lines to meet the needs of today’s agricultural market. In this article, we will explore the pathway for digital upgrades in China organic fertilizer production line businesses, focusing on the key processes and advantages these changes bring.

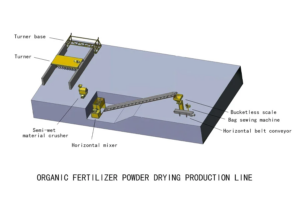

Essential Components of Powdered Organic Fertilizer Production

The China organic fertilizer production line consists of several crucial steps, from the mixing of raw materials to the final packaging. The pre-treatment process, including the blending of compost and compound bacteria, plays a significant role in preparing the materials for fermentation. For small and medium-sized enterprises (SMEs), upgrading to more automated and digital systems can improve the accuracy of material mixing and fermentation control.

At Xincheng, we provide systems that ensure efficient and controlled fermentation, reducing human error and speeding up the process. Our equipment, such as the fermentation tumbler, enables consistent and optimal aerobic fermentation, with automated monitoring systems that track temperature and humidity. This level of control ensures that each batch of organic fertilizer is of the highest quality and consistency, minimizing waste and maximizing productivity.

Integrating Automation for Efficient Control

Automation is one of the core elements of organic fertilizer production lines that can significantly enhance efficiency and reduce operational costs. The integration of automatic feeding, mixing, screening, and drying systems ensures that production runs smoothly and with minimal human input.

Xincheng offers a fully automated China organic fertilizer production line, equipped with intelligent control systems that streamline each step of production. The automatic drying system is particularly beneficial for maintaining optimal moisture content in the raw materials, ensuring the final product is dry and powdery. These automated processes not only improve the consistency of the fertilizer but also reduce labor costs, making it an attractive option for SMEs looking to increase output without increasing workforce size.

Intelligent Monitoring and Quality Assurance

Incorporating intelligent monitoring systems into the production process is another critical aspect of modernizing organic fertilizer production lines. The use of sensors and data tracking software allows companies to monitor every step of the production process in real-time, ensuring that all parameters remain within the required range. This system is particularly important for maintaining the quality of the final product, as it provides continuous feedback on material conditions, machine performance, and environmental factors.

At Xincheng, we have designed China organic fertilizer production line systems that integrate cutting-edge technology for intelligent monitoring. With these systems in place, businesses can trace the quality of their products from start to finish, ensuring that the fertilizers produced meet industry standards. The ability to monitor and adjust in real-time greatly enhances the quality control process, providing a reliable and consistent product to customers.

Return on Investment for Customized Production Lines

For small and medium-sized enterprises, customizing the production line to suit their specific needs can significantly enhance the organic fertilizer production line’s return on investment. Xincheng understands that each company has different operational requirements, and we offer flexible, tailor-made solutions that optimize production output while minimizing waste. By investing in customized production lines, businesses can see a rapid return on their investment, as they can produce high-quality fertilizer more efficiently.

Conclusion: Empowering SMEs with Digital Upgrades

Digital upgrades in the organic fertilizer production lines of small and medium-sized enterprises are a key factor in staying competitive in the market. At Xincheng, we provide systems that enhance efficiency, improve product quality, and ensure consistent results. By integrating automation, intelligent monitoring, and customized solutions, SMEs can greatly improve their production capabilities. The digital transformation of their production lines not only boosts productivity but also contributes to sustainable growth in the agricultural industry.