When we build large-scale fertilizer production lines at Xincheng, the first system we stabilize is the Fertilizer Automatic Batching System. In high-output environments, steady material flow decides whether the whole production line performs well. That’s why we design every Fertilizer Automatic Batching System with long-term continuity, accuracy, and structural clarity in mind, especially when working with farms or enterprises handling complex formulations.

Core Requirements for High-Efficiency Batching in Large Plants

Every large fertilizer factory shares the same pressure point: the line must run continuously without losing proportioning accuracy. Daily operations demand consistent feeding performance, tight error tolerance, and equipment that keeps up with the pace of granulation, mixing, and drying. Our approach at Xincheng is to let the batching module form the foundation of the process, so the downstream equipment receives a stable, predictable flow of materials. The Fertilizer Automatic Batching System also needs to respond quickly to recipe changes, something that large factories encounter frequently when producing multiple blends.

How a Continuous Batching System Operates and Its Structural Logic

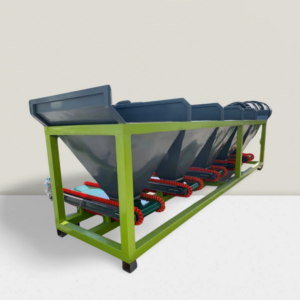

A steady production line starts with a well-planned batching layout. Our systems rely on streamlined material channels, robust weighing modules, and responsive control logic. The core component—the Dynamic Automatic Batching Machine—plays an essential role in maintaining uninterrupted proportioning. It supports continuous feeding, precise adjustment of material ratios, and stable throughput, which is vital for high-volume production. By structuring the equipment around clean flow paths and predictable cycle timing, we help factories reduce waiting time between processes and eliminate sudden material surges.

Maintaining Stability and Error Control During Continuous Production

Any pause, overload, or proportioning deviation can disrupt the entire line, so error control is a central element of the batching design. We focus on monitoring systems that track flow rate and timely correction. The Dynamic Automatic Batching Machine provides steady material distribution by adjusting feeding curves in real time, reducing fluctuations while running nonstop. This stability becomes especially important when the batching system works directly with mixers, granulators, and dryers, where consistency affects both output rate and product quality.

Conclusion

A well-designed batching setup determines how smoothly the rest of the production line performs. When the system stays continuous and accurate, downstream units—mixing, granulation, screening, drying, and packaging—operate with fewer interruptions and improved uniformity. At Xincheng, our goal is to help factories build a Fertilizer Automatic Batching System that strengthens capacity, improves long-term reliability, and supports stable product quality across every production cycle.