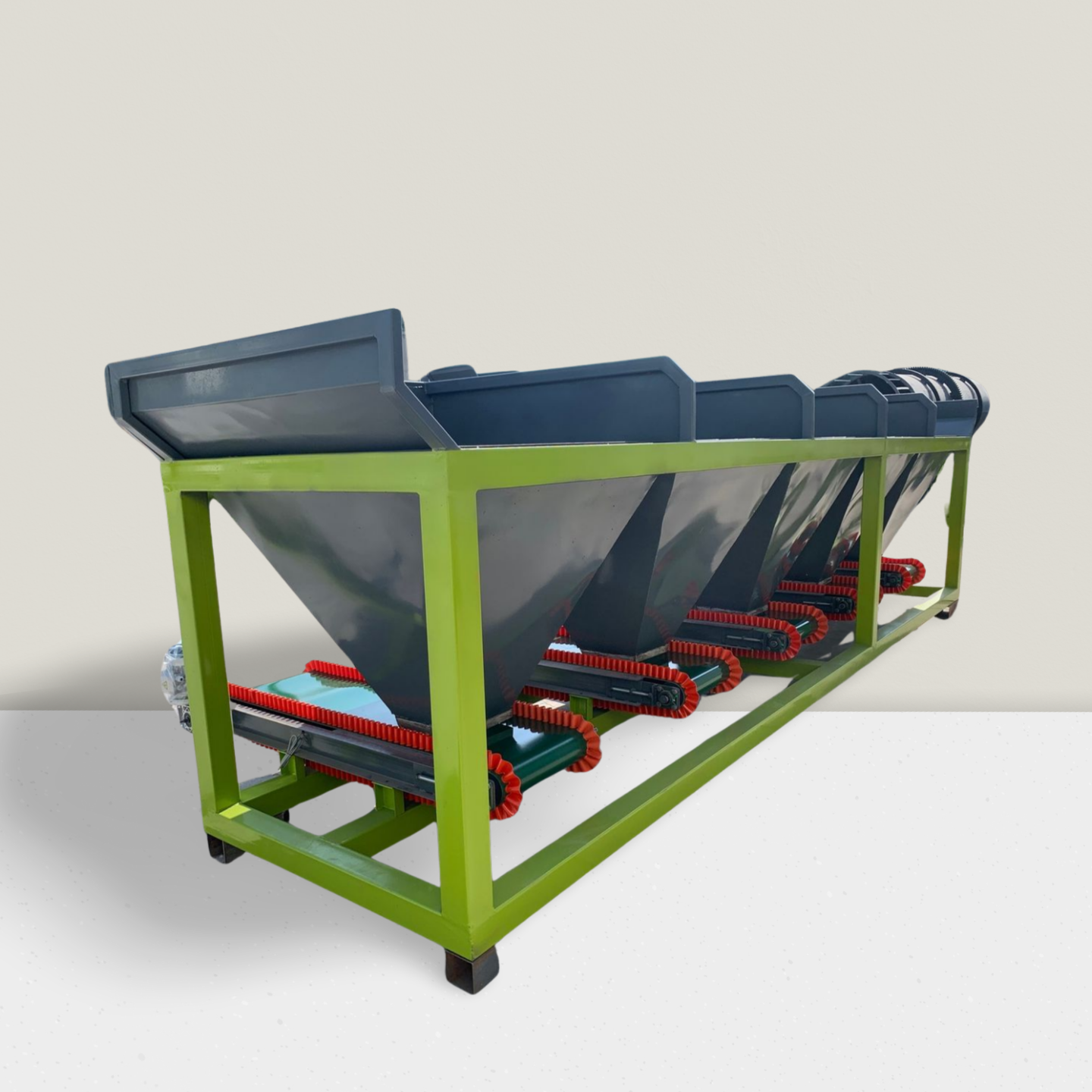

Description

Functions and features

Enhanced Product Quality and Dosage Control

– The Automatic Dynamic Batching Equipment improves product quality by precisely weighing and dosing materials through a revolving door.

– Equipped with a dosage control system that includes a robust production data statistics function, aiding effective production management.

Versatile Material Handling Capabilities

– This automatic batching system handles various materials and includes functions such as storage, conveying, weighing, batching, dust removal, mixing, packaging, and filling.

Precise Measuring and Automation Features

– Typically uses an electronic belt conveyor or nuclear scale as metering equipment, ensuring accurate batching.

– The mainframe includes PID regulation and alarm functions for automated bin control, making it highly adaptable for various dynamic automatic batching applications

Advantages of Automatic Dynamic Fertilizer Batching Machine:

1. The fertilizer automatic batching system is suitable for single-bag batching, single-bag mixing, and single-bag packaging, and can batch 5~10T per hour;

2. The dynamic automatic batching system has many types of batching and can batch 4~6 materials;

3. Ingredient accuracy is 0.5%, packaging accuracy is 0.2%

4. The dynamic fertilizer batching system can change the formula at any time for various needs

5. The dynamic batching system has a printing function and can print reports at any time;

6. The dynamic automatic mixing and batching system has LAN or remote monitoring system functions, and is connected to a large screen to display the current ingredient.

7. The dynamic batching system occupies a small area (overground, underground, semi-underground)

The organic fertilizer dynamic automatic batching machine detects the quality of the materials passing through the metering rack to determine the quality of the materials on the tape; the digital speed sensor at the tail continuously measures the running speed of the feeder, and the pulse output of the speed sensor is proportional to the speed of the feeder; the speed signal and the weight signal are sent to the feeder controller, which is processed by the German microprocessor to generate and display the cumulative/instantaneous flow. The flow is compared with the set flow, and the control instrument outputs a signal to control the frequency converter, thereby achieving the requirement of quantitative feeding.

Working principle

The Dynamic Fertilizer Batching Machine uses a measuring rack to detect the quality of materials when they pass through. This helps ensure that only high-quality materials are processed.

A digital speed sensor at the end of the feeder continuously measures its running speed. And the output from this sensor is proportional to the feeder’s speed. Both the speed and weight signals are sent to the feeder controller.

Using a German microprocessor, the system calculates and displays both cumulative and instantaneous flow rates. This flow is then compared to a preset statistic, allowing the control equipment to signal to the frequency converter, by this way can ensure accurate and quantitative feeding. This technology exemplifies the efficiency of the China Dynamic Automatic Batching System.

Suitable for people:

The fertilizer automatic automatic batching system can be used in the fields of automatic batching of metallurgical production lines, automatic batching of cement production lines, automatic batching of rubber production lines, automatic batching of mixing stations, automatic batching of compound fertilizer production lines, etc.

product properties:

| model | Feed capacity (L) | Operation cycle (S) | Ingredient error< | Productivity (m3/hour) | Belt speed (M/S) | Motor power (kw) | Mass (Kg) |

| PLD1200 | 1200 | 60 | ±2% | 56 | 1.25 | 15 | 4500 |

| PLD1600 | 1600 | 60 | ±2% | 75 | 1.6 | 27.5 | 5600 |

| PLD2400 | 2400 | 60 | ±2% | 120 | 1.6 | 11 | 8500 |

| PLD3200 | 3200 | 60 | ±2% | 160 | 1.6 | 15 | 10200 |

Reviews

There are no reviews yet.