Description

Advantages:

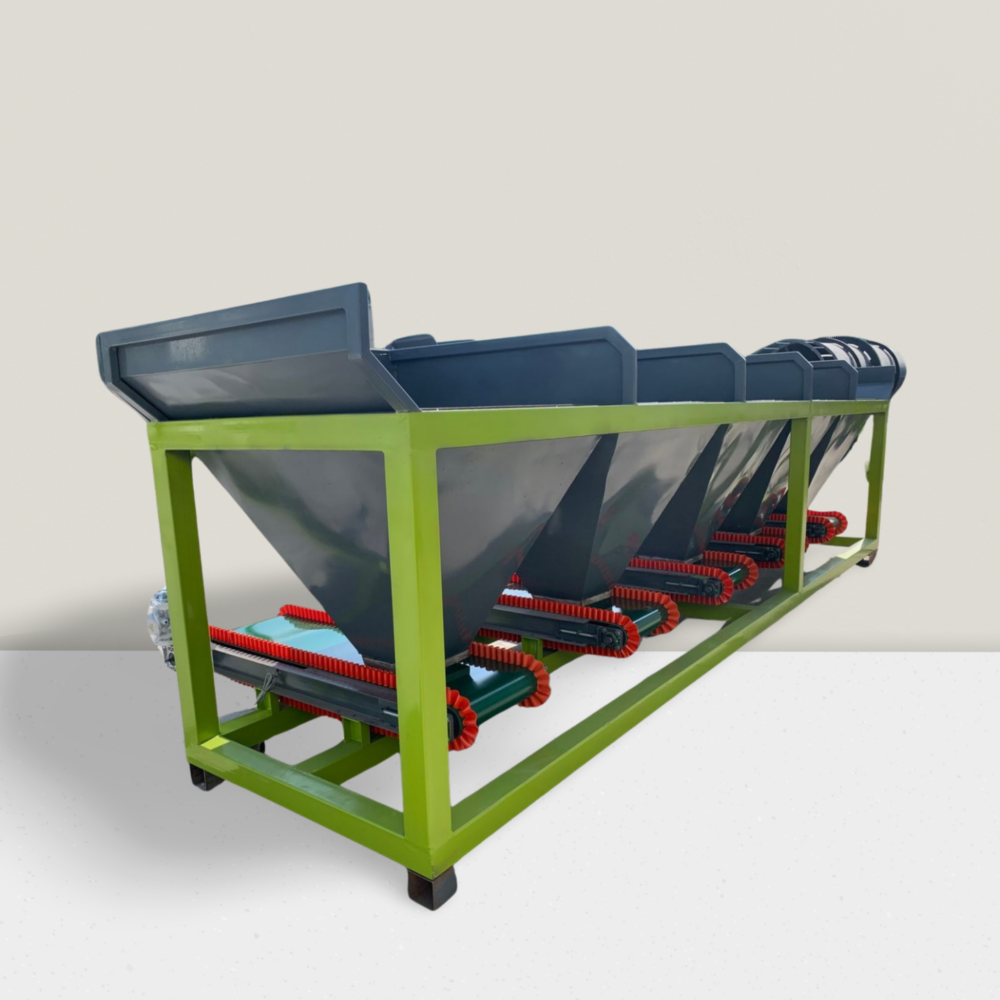

The static automatic batching machine for organic fertilizer adopts microcomputer control, electronic monitoring, digital prompts, and wired remote control. It has multiple structural forms, flexible combination methods, high weighing accuracy, high degree of automation, fast batching speed, many types of batching, good control function, continuous batching of various materials at the same time, reasonable design, convenient operation, easy control, and meets the requirements.

Usage and Application:

The organic fertilizer static automatic batching machine consists of aggregate storage hopper, belt conveyor, metering system, weighing hopper, frame, electronic control system, etc. A weighing silo is configured under each storage silo, one silo one scale, continuous weighing and continuous batching. During the batching process, various materials are fully mixed, reducing the working intensity of the mixer.

Suitable for people:

1. Construction industry: used for storage and transportation of cement, sand, concrete and other construction materials.

2. Chemical industry: used for storage and transportation of chemical raw materials such as fertilizers, liquids, powders, etc.

3. Agricultural industry: used for storage and transportation of agricultural products such as grains, seeds, feed, etc.

4. Mining industry: used for storage and transportation of ore, coal, limestone and other mining products.

Widely used, food, feed. Chemical, refractory materials, starch, pigment powder, pectin powder, fish meal,

Flower nutrient soil, coal washing, fertilizer, ore, sand, clay, kaolin

product properties:

| model | Feed capacity (L) | Operation cycle (S) | Batching error < | Productivity (m3/h) | Belt speed (M/S) | Motor power (kw) | Mass (Kg) |

| PLD1200 | 1200 | 60 | ±2% | 56 | 1.25 | 15 | 4500 |

| PLD1600 | 1600 | 60 | ±2% | 75 | 1.6 | 27.5 | 5600 |

| PLD2400 | 2400 | 60 | ±2% | 120 | 1.6 | 11 | 8500 |

| PLD3200 | 3200 | 60 | ±2% | 160 | 1.6 | 15 | 10200 |

Reviews

There are no reviews yet.