Organic fertilizers play a crucial role in today’s agriculture, supporting soil health and improving crop yields while also reducing the environmental impact of synthetic fertilizers. The process of creating these fertilizers involves several key stages, each critical in ensuring the end product meets the needs of modern farming. The organic fertilizer granulation production line is central to this process, turning raw materials into nutrient-dense, easy-to-apply granules. At Xincheng, we emphasize efficiency and precision at every stage, from raw material processing to packaging.

Step 1: Preparing Raw Materials for Granulation

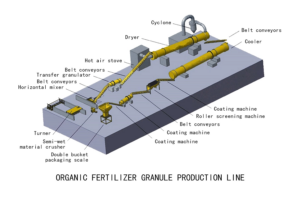

The first phase in the organic fertilizer granulation production line is the treatment of raw materials. At Xincheng, we prioritize efficient fermentation, crushing, and mixing of organic waste, which are essential for maximizing nutrient availability and consistency. During fermentation, materials are broken down by microorganisms to release valuable nutrients, while the crushing process ensures the materials are finely ground. The mixing system then guarantees an even distribution of nutrients, setting the foundation for high-quality fertilizer granules.

Step 2: Granulation Equipment and Quality Assurance

The heart of the production line is the granulation process. At Xincheng, our equipment uses advanced technology to create granules with consistent size and shape. The organic fertilizer granule production line ensures that nutrients are uniformly distributed in each granule, optimizing the product’s effectiveness in the field. Our batching system provides precise control over the ingredients, ensuring the product meets the required standards. With reduced dust and breakage, the granules are both easy to apply and transport.

Step 3: Drying, Cooling, and Screening for Consistency

Once the granules are formed, they must be dried, cooled, and screened. The drying process is essential to remove moisture from the granules, stabilizing them and preventing degradation. At Xincheng, we use advanced drying equipment that quickly removes water, preserving the quality of the final product. The cooling system ensures the granules do not stick together, and the screening process ensures that only high-quality granules reach the packaging stage, free from any undersized particles.

Step 4: Automation and Efficiency in the Production Line

In today’s competitive agricultural industry, automation and energy efficiency are crucial. At Xincheng, we have invested in cutting-edge automation technology to optimize every step of the organic fertilizer granulation production line. This allows us to reduce manual intervention while maintaining consistent quality and high output. Additionally, our production line is designed to minimize energy usage, reducing both operational costs and our environmental footprint.

Conclusion: Ensuring Quality and Efficiency in Organic Fertilizer Production

The organic fertilizer granulation production line at Xincheng represents the ideal combination of technology, efficiency, and sustainability. By optimizing each phase of the process—from raw material preparation to packaging—we are able to provide a reliable, high-quality product that helps farmers achieve better crop yields while maintaining soil health. With a focus on precision, automation, and energy efficiency, Xincheng ensures that our organic fertilizer granule production line meets the demands of modern agriculture.