Organic Fertilizer Granulation Line

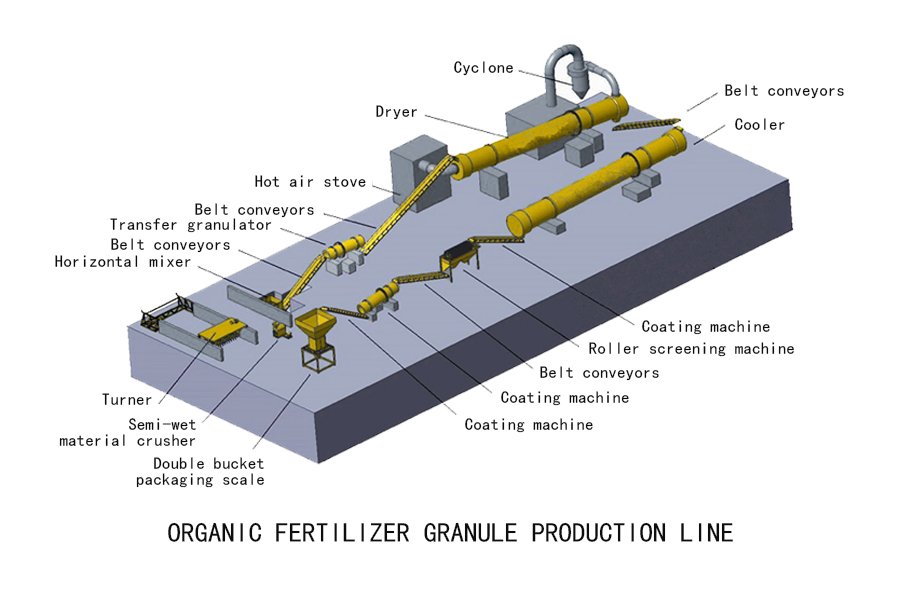

Raw material fermentation → forklift silo unloading → crushing → mixing → granulation → drying → cooling → screening → coating → packagingDetailed Information of our granular organic fertilizer production line

- During the organic fertilizer granulation line, the crushing equipment first fully crushes the raw materials to a state that is suitable for processing.

- Then, through a precise batching system, various nutrients are rationally distributed to ensure that the organic fertilizer particles are nutritionally balanced.

- Besides, fertilizer granulation equipment begins to work, processing the mixed raw materials into particles of uniform size and regular shape.

- Finally, the drying system will quickly remove water from the pellets to improve the stability and shelf life of the product. The cooling system will rapidly cool down the hot pellets to ensure the product quality is not affected.

No products were found matching your selection.

FAQs

Why Organic Fertilizer Granulation equipment is necessary for agriculture production?

Organic fertilizer granulation machine is also named organic fertilizer pellet machine, which plays an important role in organic fertilizer granule production line because it can granulate the loose organic fertilizer into granules. With this machine, the fertilizer can be easier to store.What are the advantages of granular organic fertilizer?

- Fertilizers with low water solubility often require processing into a smaller one by the organic fertilizer granule production lines so as to faster dissolution and plant absorption.

- Controlling fertilizer particle size is essential for effective storage and transportation. Proper granulation from the granular organic fertilizer production line prevents clumping and is beneficial to transportation.

- The organic manure granulation production line allows adding inorganic ingredients to improve the effectiveness of organic fertilizers.

- Fertilizer granulation improves agricultural efficiency by ensuring slow-release features, which are supported by organic fertilizer granulation systems, preventing fertilizer loss caused by the wind.

What kind of fertilizer granulation equipment do we have?

- Double roll extrusion granulator

- Agitator organic fertilizer granulator

- Rotating and stirring gear two-in-one granulator

- Three-in-one granulator with rotating gear

- Strand granulator

- Disc granulator

Why Organic Fertilizer Granulation is better than Chemical Fertilizer?

For agricultural production, fertilizer granulation is important for organic production. The following are the benefits of fertilizer granulation equipment for organic production- Chemical fertilizers pollute the environment, while organic fertilizer granulation produced by organic fertilizer rounders converts waste into valuable organic fertilizers.

- Organic fertilizer contains more nutrients compared to chemical fertilizers and can provide plants with more comprehensive nutrients. The organic fertilizer granule production line can help to produce organic fertilizer so that to make the soil more fertile.

- Bio-organic fertilizer improves the quality of plants, while chemical fertilizers may harm to the quality of plants. The use of organic fertilizers can increase the resistance of plants to pests and diseases.

- Chemical fertilizers pollute the environment, whereas organic manure granulation production line produces organic fertilizers that convert waste into useful organic fertilizers and reduce pollution.