Functional characteristics:

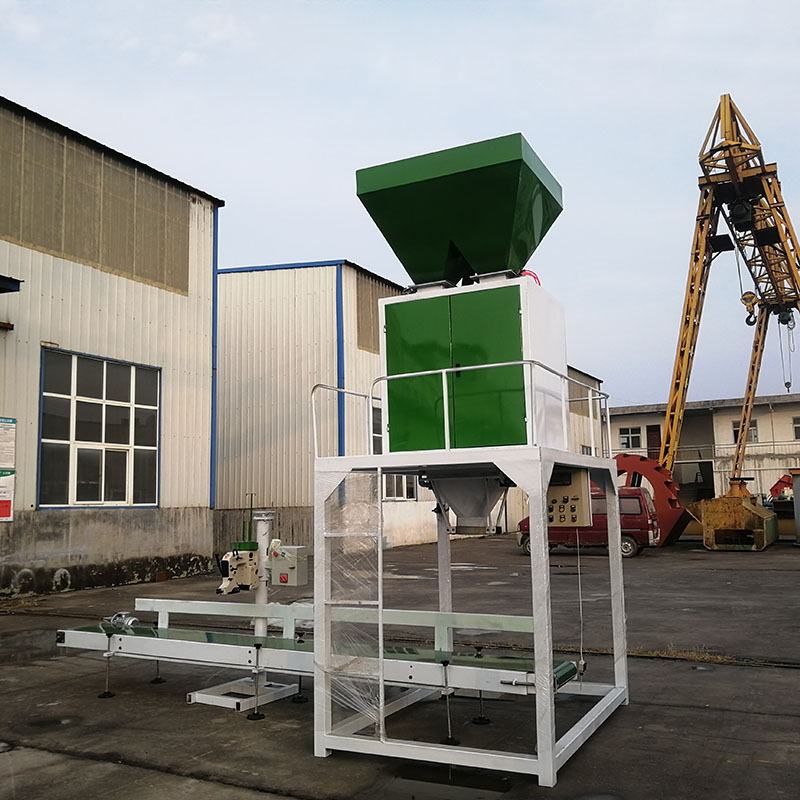

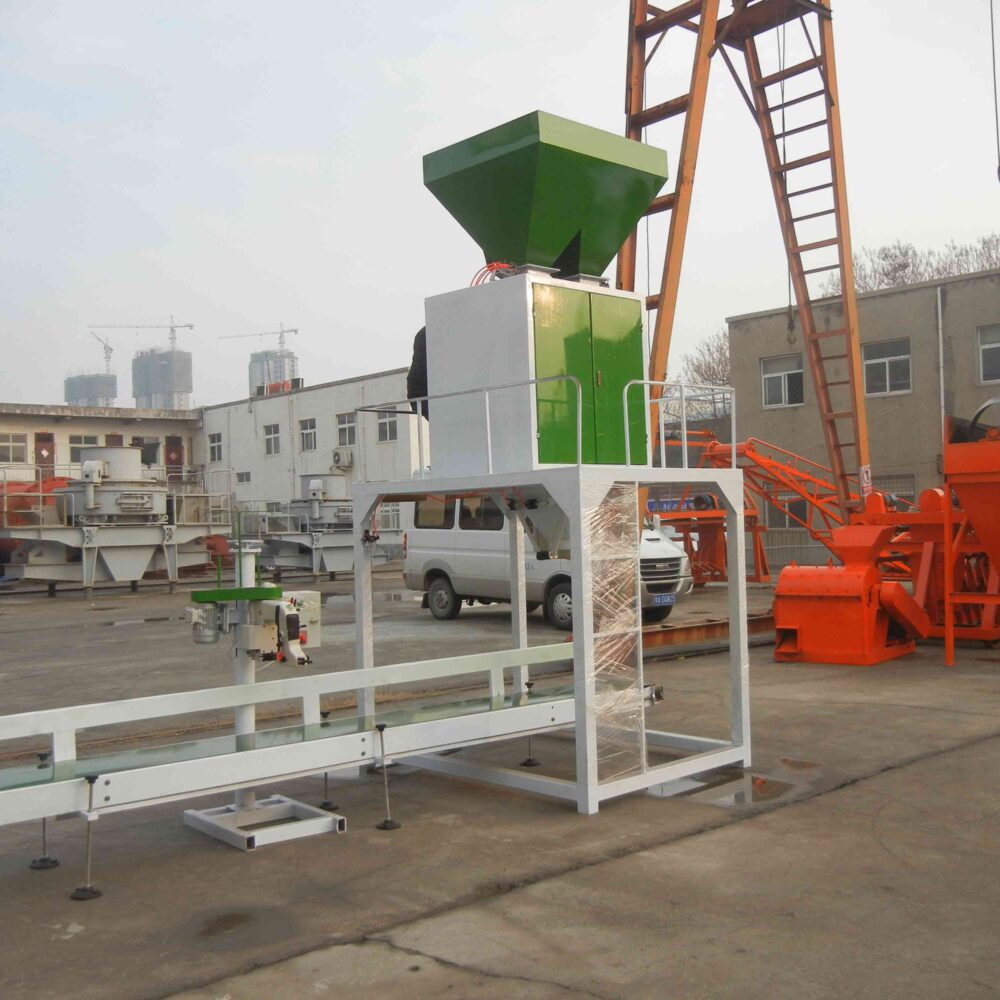

Ton bag machine: It is tailor-made and designed according to the characteristics of powder materials and the different requirements of manufacturers. It is mainly used for large-scale weighing packaging equipment for large-bag packaging materials; It is mainly used for large-scale weighing packaging equipment for large-bag packaging materials. It is a multi-purpose quantitative packaging machine integrating electronic weighing, automatic bag removal and dust removal.

Ton bag machine: It is a multi-purpose packaging machine integrating electronic weighing, automatic bag removal and dust removal. The machine has a high degree of automation, stable equipment performance, high packaging accuracy, and the packaging speed can be adjusted with production; the equipment technology is durable and has few vulnerable parts; the programmable electronic control system has a highly reliable control process. The dust-proof and dust removal design is adopted to reduce dust pollution in the working environment.

Ton bag packaging machine is a large-scale weighing packaging equipment for ton bag packaging materials. It is a multi-purpose packaging machine integrating electronic weighing, automatic bag removal and dust removal. It has a high degree of automation, high packaging accuracy, adjustable packaging speed, superior structure, and the hydraulic lifting system is particularly easy to handle ton bag packaging, and it is very convenient for the processing of subsequent processes. Ton bag packaging machine is suitable for packaging materials in ton bags in the mining, chemical, building materials, grain and feed industries.

The ton bag machine consists of a boom, a hook, a bucket, a rotating mechanism, a conveying mechanism, a control system and other parts. When working, the material is first shoveled into the bucket, then transported to the destination through the conveying mechanism, and then dumped into the ton bag through the rotating mechanism. During the conveying process, the control system can adjust the conveying speed, conveying volume, rotation angle, etc. of the material. The boom and hook can move forward and backward, up and down, left and right to facilitate the handling and fixing of ton bags. The ton bag machine adopts a variety of technical means such as mechanical, electrical, and hydraulic, which can ensure efficient, safe and stable operation in different environments

Bulk particles, powders, irregular flake materials 250 kg – 2000 kg ton bags container bags automatic weighing and packaging