Description

Advantages:

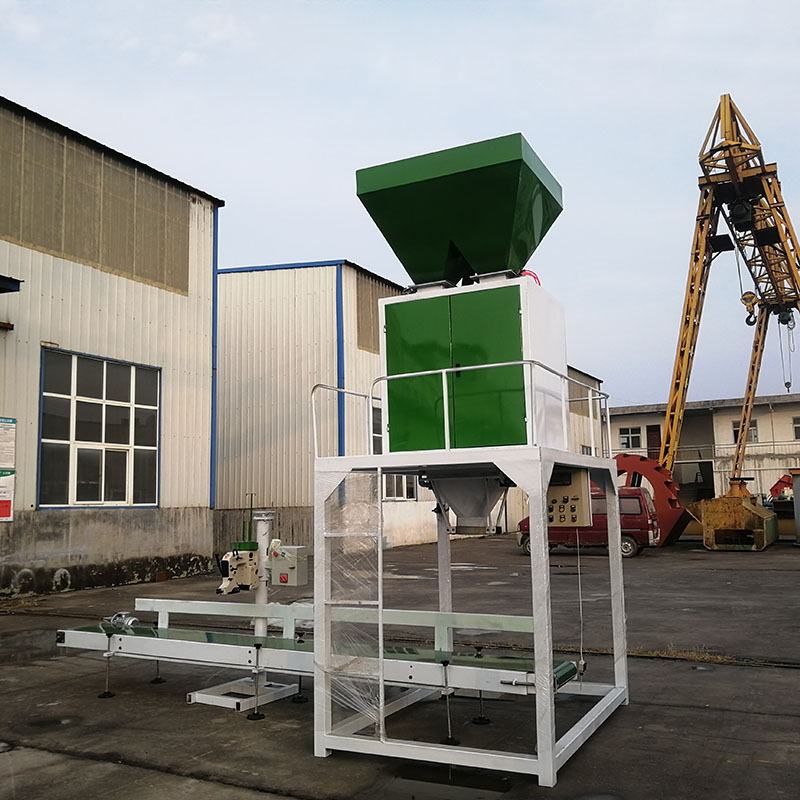

Ton packing machine: The weighing system is an electronic platform scale, which uses digital calibration and parameter setting. It has functions such as weight accumulation display, automatic peeling, automatic zeroing, and automatic drop correction. It has high sensitivity and strong anti-interference ability. The instrument is equipped with a communication interface for easy online networking, and can monitor and manage the packaging machine in real time.

Technical features of ton charter machine

1. Ton charter machine technology, durable, with few vulnerable parts;

2. No speed adjustment for feeding and packaging, stable equipment performance, fast packaging speed;

3. Programmable electronic control system to control the degree of over-burden;

4. Dust-proof and dust-removal design to reduce dust pollution in the working environment;

5. The weighing system is an electronic scale platform scale measurement, which adopts digital adjustment and parameter setting of the entire panel, with weight accumulation display and automatic peeling, automatic zeroing, automatic drop correction and other functions, with strong sensitivity and anti-interference ability;

6. The instrument is equipped with a communication interface, which is convenient for online networking, and can be used for real-time monitoring and network management of ton charter machines;

7. Strong load-bearing capacity: Ton bags are made of high-strength synthetic fiber materials and can bear a lot of weight.

8. Long service life: Ton bags have been specially processed and have excellent durability and waterproofness, and have a long service life.

9. Low cost: The production cost of ton bags is relatively low, and they can be used repeatedly, and the cost of use is not high.

10. Easy to operate: Ton bags can be mechanized, which improves work efficiency and reduces the intensity of human labor

Usage and purpose:

The machine has a wide range of applications, high packaging accuracy, good performance and high quality. Including pneumatic hook clamping system, air filling and air return mechanism, feed metering control mechanism, hydraulic lifting mechanism, conveyor roller, electrical control, etc.

Most grain materials, such as wheat, corn, soybeans, etc., can be packaged using ton bag packaging machines, so as to better ensure the freshness and safety of the materials. At the same time, the packaging quality of the ton bag packaging machine can also be effectively guaranteed to ensure the integrity of the materials.

Chemical materials, such as sulfuric acid, hydrochloric acid, etc., can also be packaged using ton bag packaging machines, which can effectively prevent the leakage of chemical substances and ensure their safety. At the same time, the ton bag packaging machine can also effectively improve the quality of the materials and ensure the uniform quality of each bag of materials.

Cement materials, such as cement, lime, etc., can also be packaged using ton bag packaging machines, which can effectively ensure the freshness and safety of cement, thereby improving the quality of construction. At the same time, the ton bag packaging machine can effectively improve the appearance of the materials and ensure the consistent appearance of each bag of materials.

Suitable for people:

Usage scenario Ton bag packaging machine is mainly used for packaging bulk materials, and is widely used in chemical, grain, building materials, fertilizer, organic fertilizer, ore, and other industries.

1. Construction industry: used for storage and transportation of cement, sand, concrete and other building materials.

2. Chemical industry: used for storage and transportation of fertilizer, liquid, powder and other chemical raw materials.

3. Agricultural industry: used for storage and transportation of agricultural products such as grain, seeds, and feed.

4. Mining industry: used for storage and transportation of ore, coal, limestone and other mining products.

Widely used, grain, feed. Chemical, refractory materials, starch, pigment powder, pectin powder, fish meal,

product properties:

| model | Weighing range | Bagging capacity | Accuracy | Working power supply | Air pressure | Gas consumption | Dust removal air volume | Relative humidity | product material |

| XS-1000 | 500-1000 kg/bag | 15-30 tons/hour | Dynamic weighing ±0.5% | 380V, 50HZ, 11kw | 0.5Mpa | 0.6m3/min | 800-2500 m3/min | ≤80% Ambient humidity: -100C-400C | Carbon steel stainless steel |

| XS-1200 | 500-1200 kg/bag | 10-30 tons/hour | Dynamic weighing ±0.2% | 380V/220,50HZ,6kw | 0.5Mpa | 0.6m3/min | 800-2500 m3/min | ≤80% Ambient humidity: -10~40℃ | Carbon steel stainless steel |

Reviews

There are no reviews yet.