In recent years, the demand for granular organic fertilizers has seen significant growth in the agricultural sector. This surge is driven by the increasing need for sustainable farming practices and environmentally friendly fertilizers that promote soil health. At Xincheng, we understand this growing need and offer an advanced organic fertilizer granulation system designed to efficiently produce high-quality organic fertilizers. By integrating cutting-edge technology and streamlined production processes, we enable farmers to optimize their fertilizer production while ensuring the final product’s effectiveness and sustainability.

Main Equipment of the Granulation Line: Structure and Function

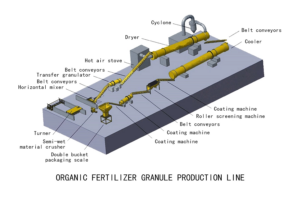

The organic fertilizer granulation line consists of several key pieces of equipment, each playing a critical role in the production process. These include the raw material fermentation system, crushing equipment, mixing unit, granulation machine, drying system, and cooling system. The fermentation unit ensures that raw materials, such as manure or agricultural waste, undergo biological transformation to become safe and nutrient-rich. The crushing equipment reduces the raw materials to a suitable size, enabling uniform mixing and granulation.

In the granulation stage, the granulator processes the mixture into uniform particles, ensuring consistency in size and shape. This is crucial for ensuring that the fertilizer disperses evenly in the soil, providing a balanced nutrient supply to plants. Finally, the drying and cooling systems work together to remove excess moisture from the pellets, enhancing their shelf life and preventing deterioration during storage and transportation.

Granulation System Performance and Technology

At Xincheng, our organic fertilizer granulation system incorporates advanced technologies that ensure optimal performance throughout the production line. The granulation equipment is designed to efficiently convert organic raw materials into high-quality fertilizer pellets. The granulator is equipped with precision control mechanisms that ensure the particle size remains consistent and the nutrient distribution is balanced.

Additionally, the granulation process is carefully monitored to ensure the right moisture content for each batch. This not only improves the effectiveness of the fertilizer but also minimizes waste, making the process more cost-effective. Our system is engineered to operate smoothly, reducing downtime and enhancing overall production efficiency.

Impact of Drying and Cooling Equipment on Product Quality

The drying and cooling systems are pivotal in ensuring that the organic fertilizer pellets maintain their quality and stability. At Xincheng, our advanced drying system uses controlled temperature settings to rapidly reduce moisture content from the pellets, ensuring that they are dry without compromising nutrient integrity. This is critical, as excess moisture can cause pellets to degrade and lose their efficacy.

Once dried, the pellets are rapidly cooled by our cooling equipment. The cooling process is essential to stabilize the fertilizer, preventing clumping and ensuring that the product maintains its shape during storage and transport. Proper cooling also helps extend the shelf life of the fertilizer, allowing farmers to store it for longer periods without losing effectiveness.

Key Considerations for Operation and Maintenance

Effective operation and regular maintenance are key to ensuring the long-term efficiency of any organic fertilizer granulation line. At Xincheng, we emphasize the importance of routine checks and timely maintenance to avoid equipment malfunctions. Regular inspection of the crushing and mixing units, granulation machines, and drying systems ensures smooth operation and prevents unexpected downtime.

Proper training for operators is also essential to maintain the efficiency of the production line. By ensuring that all staff are well-versed in equipment operation and troubleshooting, we can minimize errors and improve the overall output of the fertilizer production process.

Conclusion: The Critical Role of Equipment Structure in Production Efficiency

The structure and functionality of each component in an organic fertilizer granulation line play a significant role in determining overall production efficiency. At Xincheng, our comprehensive system design ensures that every stage, from raw material processing to final product packaging, is optimized for performance. By using high-quality, durable equipment, we can offer our clients a reliable and efficient solution for organic fertilizer production, contributing to a more sustainable agricultural industry.