In the world of agriculture, the demand for efficient and eco-friendly fertilizers is constantly growing. With the shift toward organic farming, the use of organic fertilizers has seen a significant rise. At Xincheng, we understand that to meet this demand efficiently, automation and smart technology play a key role in improving production processes. Our Organic fertilizer pellet production line is a prime example of how automation is revolutionizing fertilizer manufacturing. In this article, we’ll explore how Organic manure granulation production line technologies are advancing with automation and intelligence to enhance production efficiency and sustainability.

Integration of Automated Control Systems in Fertilizer Lines

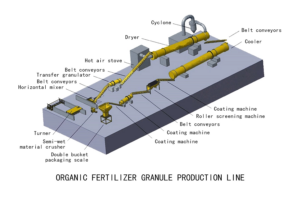

In our Organic fertilizer pellet production line, automation is at the heart of the process. We’ve incorporated advanced control systems that seamlessly integrate every step from raw material processing to the final product. These systems ensure consistency and reduce human error, allowing the granulation process to be monitored and controlled more accurately. The inclusion of PLCs (programmable logic controllers) and SCADA (Supervisory Control and Data Acquisition) systems ensures that the entire process is optimized for maximum output and minimal downtime.

At Xincheng, we focus on designing equipment with the latest automated features, such as real-time monitoring of raw material input and granule size control. These improvements not only streamline the production process but also reduce operational costs by minimizing waste and energy consumption.

Smart Monitoring and Quality Tracking for Consistency

One of the major challenges in organic fertilizer production is ensuring that each batch of granules maintains high quality. By using smart monitoring technologies in our Organic manure granulation production line, we can track and control the size, shape, and moisture content of every granule produced. This level of precision is crucial for maintaining the efficiency of the fertilizer, as it directly impacts the nutrient release rates and soil absorption.

Xincheng’s smart systems can detect deviations in the process and automatically adjust parameters to maintain consistent product quality. Whether it’s adjusting mixing times or granule moisture, our equipment uses real-time data to ensure that each granule meets the desired specifications.

Improving Efficiency and Reducing Costs with Smart Technology

At Xincheng, we’re committed to enhancing productivity while keeping costs low. Our Organic fertilizer pellet production line incorporates energy-efficient motors, optimized material handling systems, and high-performance granulators that reduce waste and increase the production rate. These technological advancements result in lower operational costs and a higher return on investment for our clients.

By using Organic manure granulation production line equipment that intelligently adjusts to different materials, we can help reduce energy consumption and raw material wastage. This is crucial for companies looking to scale up production while keeping their environmental impact to a minimum.

Environmental and Safety Benefits of Automation

Automated systems in fertilizer production lines also bring environmental and safety benefits. At Xincheng, we are committed to promoting sustainability in agriculture. Our Organic fertilizer pellet production line minimizes the need for chemical additives and reduces the use of harmful substances, making the final product safer for both the environment and the crops. Additionally, our automated safety features, such as emergency stop systems and remote monitoring, ensure that operations are carried out safely, reducing the risk of accidents and improving worker safety.

Conclusion: Paving the Way for the Future of Organic Fertilizer Production

In conclusion, the development of automated and intelligent systems in organic fertilizer production is transforming the agricultural industry. At Xincheng, we are proud to be part of this evolution with our Organic fertilizer pellet production line and Organic manure granulation production line. By incorporating advanced automation and smart technology, we can offer solutions that not only increase efficiency and quality but also contribute to a more sustainable and cost-effective production process. The future of organic fertilizer production is undoubtedly smarter and more sustainable, and at Xincheng, we are ready to lead this change.