In the agricultural industry, there’s an increasing demand for flexible, high-capacity solutions in fertilizer production. With organic farming gaining traction worldwide, the organic fertilizer granulation production line has become crucial in ensuring efficient and sustainable fertilizer production. At Xincheng, we understand that the needs of different production scales vary significantly, and each scale requires specific equipment configurations to optimize efficiency, cost, and output. From small agricultural cooperatives to large industrial factories, having the right setup is essential to meet growing market demands.

Production Line Configuration for Small-Scale Agricultural Cooperatives

Small agricultural cooperatives often face budget constraints and the need for flexibility in their operations. For them, an organic fertilizer granule production line must strike a balance between cost and functionality. At Xincheng, we offer compact, cost-effective solutions that can efficiently process organic waste into granules. Typically, small-scale systems require machines like the disc granulator, which offers high granulation rates and low maintenance costs. These setups help small cooperatives increase production while keeping their investment manageable. The smaller footprint of these systems allows for easy integration into existing operations, ensuring that even limited space does not become a barrier to success.

Equipment Layout and Capacity Balancing for Mid-Scale Production Plants

Mid-sized production plants require a more sophisticated configuration, balancing the demand for higher output with the available space and investment. In this scenario, an organic fertilizer granulation production line should incorporate more advanced equipment, such as the rotating and stirring gear two-in-one granulator. This type of granulator not only improves efficiency but also ensures uniform granulation. Xincheng designs production lines with scalability in mind, so as businesses grow, they can upgrade their systems without significant operational disruption. The key is finding the right balance between automation, granulation rate, and energy consumption. These plants often need larger equipment with higher capacities, but the focus should still be on optimizing energy use and ensuring smooth operations.

Comprehensive Automation Solutions for Large-Scale Industrial Plants

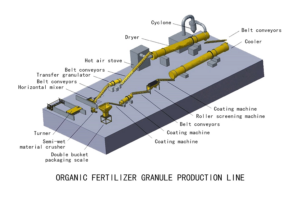

For large-scale industrial plants, automation and integration are critical to managing the high-volume production of organic fertilizers. Xincheng offers advanced, fully automated systems that streamline every aspect of fertilizer production, from raw material processing to granulation and packaging. Large-scale factories typically use high-efficiency equipment, such as the three-in-one granulator with rotating gear, which integrates mixing, granulation, and drying in one continuous process. These automated systems reduce labor costs, improve product consistency, and significantly enhance production capacity, making them ideal for large industrial-scale operations. Automation also ensures high production output with minimal downtime, further driving efficiency.

Investment and Operational Costs: Comparing Returns on Different Scale Configurations

When investing in an organic fertilizer granule production line, understanding the costs and potential returns is essential. For small cooperatives, the initial investment may be low, but the return per unit of output could be smaller. On the other hand, mid and large-scale factories, with their higher upfront costs, can achieve a higher return on investment due to their increased output. Xincheng works with clients to ensure that their equipment choices align with their budget and production goals. Our solutions are designed to optimize long-term profitability by considering not only the initial costs but also the ongoing maintenance, operational costs, and potential for scaling up as demand increases.

Conclusion: Key Decisions for Choosing the Right Configuration

In conclusion, the configuration of an organic fertilizer granulation production line should always be tailored to the scale of production. Whether you are a small cooperative or a large industrial plant, Xincheng provides solutions that meet your unique needs. The key decision-making factors include budget, available space, production capacity, and the level of automation required. As market demands grow, having the right fertilizer granulation equipment can provide significant advantages, from improving efficiency to reducing environmental impact. At Xincheng, we work closely with clients to ensure that every production line is customized to meet their specific requirements for maximum productivity and profitability.